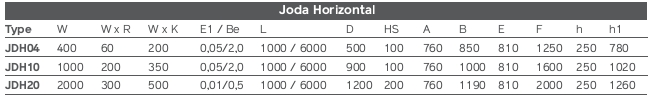

Modules of welding positioners JODA HORIZONTAL can be combined together to be able to supply 3 different sizes :

JDH04, JDH10 and JDH20 each ones consisting of :

• Headstock JDTM

• JDTF Manual tailstock or JDHC or JDHCP pneumatic tailstocks

• JDR Base, with ball bearings linear guides, covers and levelling screws, available in sections of 2 m (JDR 2000/C) or of 3 m (JDR 3000/C)

• JDSE, JDEL and IPTRE adjustable heights dollies to suit different diameters.

1. JDR 2000/C

2. JD SE

3. JDHC and JDHCP

4. JDR 3000/C

5. JD TF

6. JD EL

7. JDTM – Joda Horizontal

STANDARD FEATURES of Joda Horizontal welding positioners

• Feeding 230V 1-phase or 400V 3-phase.

• CNC Work cycle [*5].

• Weld ground : 400 A [*6].

• Remote control desk cabinet.

[*] OPTIONAL FEATURES

1. Different torque

2. Different speed range or drive

3. Pneumatic tailstock

4. Different diameter

5. Different work cycle (delayed start, 360° + x° overlapping, back stroke -0°)

6. Up to 1000 A 100%

7. Different control cabinet arrangements integrating video and joint tracking

systems and installation of Carpano’s additional equipment such as

AVC, chucks, wire feeder and so on…